Blow-moulding, container rinsing, filling and closures

Filling technology is a crucial choice to succeed for bottlers, canners and any food and beverage industry.

Filling & Packaging can offer the right solutions to accomplish all products needs in term of quality, containers and cost effectiveness to maximize clients return on investment.

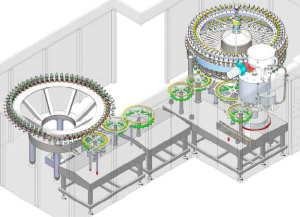

Filler machines series are able to fill cans, PET and other plastic containers, glass and jars with sensible products and CO2 added beverages, in cold or HOT FILLING. Several optional and devices are available to enrich beverages taste and sensations or adapt mono-blocks to multiple products or multiple containers handling:

- integrate juices with fibers and chunks,

- run flat and carbonated beverages,

- fill PET and glass bottles alternatively,

- perform hot or cold filling.

Filling mono-blocks or free standing fillers can be integrated with the most reliable and efficient closure systems for any kind of cap, lid and end. We are specialized in the rinsing and preparation of containers before filling and are able to propose clients with the most suitable rinsing solution.

We can propose integrated blow-moulding-filling-capping mono-blocks or integrated filling lines from the plastic container blow-moulder to the closure devices.

Filling Machine series

- UNICA SA CAN rotating filler

- FOUR ONE

- UNICA SC rotating filler

- UNICA SA rotating filler

- UNICA TRONIC rotating filler

UNICA SA CAN rotating filler

This counter pressure machine is designed and engineered for CAN FILLING & SEAMING. The machine can be assembled with different type of filling valves for any kind of product. The filling machine can be sized from 20 to 120 UNICA valves for a nominal production of 3.000 to 60.000 cans per hour.

| Packaging technology | Products/ Containers/ Closures | |

|---|---|---|

| UNICA CAN The valve is integrated inside the annular tank of the filler, it is designed to fill aluminum or steel containers. The valve offers many advantages in terms of quality, return of investment and running costs. The valves are constructed of AISI 304 and finished with accuracy resulting efficient in term of hygiene and efficiency. Main Features:

|  | Designed for BEER Other products:

|

- High quality filling technology with reduced foaming and O2 absorption and CO2 consumption.

- Soft can movement: the filling valve descends on the container and ascends after filling reducing shakes of the filled can.

- The transfer star from the filling turret to the seamer is performed with special design to optimize time phases and increase productivity reducing foam and product lost

- Optimized cost engineering for a nominal production of 3400 cans per hour

go back to filling machine series list

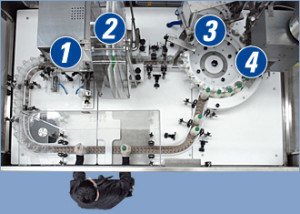

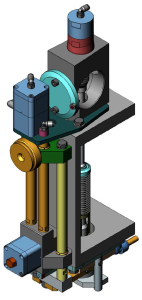

FOUR ONE

A pocket machine studied for fresh milk and juices and many other craft beverages. One operator only can produce up to 1000 bottles per hour. Rinsed, labeled, filled and closed.

| Characteristics | Products/ Containers/ Closures | |

|---|---|---|

| FOUR ONE The machine is characterized by its PATENT, a close belt transportation system running through 4 phases: LABELLING, RINSING, FILLING and CAPPING. Versions

|  | Products:

|

- Thanks to the patent the FOUR ONE filling machine is a quality and cheap filler: the perfect instrument for B2C (business to customer) market.

- FOUR OPERATIONS IN ONE MACHINE. One operator only

- Limited footprint (10 sqmt) and easy positioning

- Volumetric filling system with electronic flow meters without contacts between the bottles and the filling valve;

- Capping turret to apply different types of caps;

- Distributor for capsules made in aluminum or PVC;

- Labeling to apply Self-Adhesive label partial or Wrap-Around.

- Plug and play installation

- Limited investment compared to separate units performing the same function

go back to filling machine series list

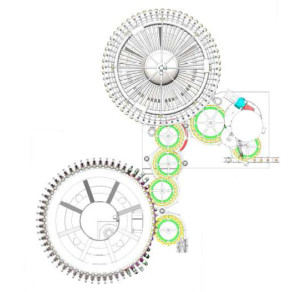

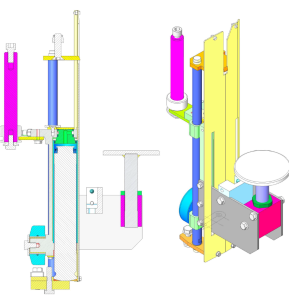

UNICA SC rotating filler

The UNICA SC machines series is the best solution for filling PET bottles. The filling machine can be sized from 20 to 120 UNICA SC valves for a nominal production of 6.000 to 36.000 bottles per hour. Thanks to its CENTRAL TANK and bottle neck handling, the structure of the machine is very simple and clean, the valves are connected with inox piping to the tank and are not plunged into the product. Bottles hang from neck pincers and are safely transferred Between wheel stars and turrets.

| Packaging technology | Products/ Containers/ Closures | |

|---|---|---|

| UNICA SC Thanks to its CENTRAL TANK and bottle neck handling, the structure of the machine is very simple and clean, the valves are connected with inox piping to the tank and are not plunged into the product. Bottles hang from neck pincers and are safely transferred between wheel stars and turrets. Optimum for neck-handling containers Main Features:

UNICA SC filler versions

|  | Designed for neck handling, Flexible to any application Products:

|

- High quality filling technology with reduced foaming and O2 absorption and CO2 consumption.

- Soft can movement: the filling valve descends on the container and ascends after filling reducing shakes of the filled can.

- The transfer star from the filling turret to the seamer is performed with special design to optimize time phases and increase productivity reducing foam and product lost

- Optimized cost engineering for a nominal production of 3400 cans per hour

go back to filling machine series list

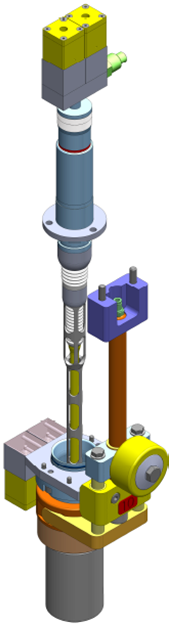

UNICA SA rotating filler

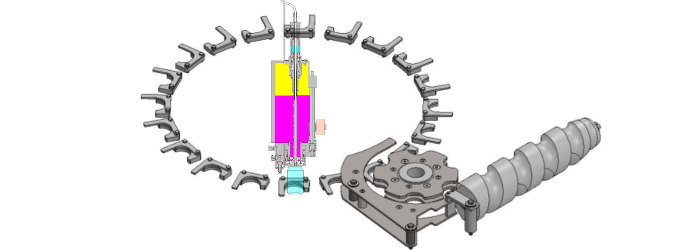

The UNICA SA machines is designed to fill GLASS Bottles. The filling machine can be sized from 20 to 120 UNICA SA filling valves. Thanks to its LIFTERS the machine handles glass bottles softly. The advanced valve allows any type of filling cycle. The UNICA SA can be adapted to run alternatively glass bottles and PET containers. Special devices can be adopted on request to neck handling. The UNICA SA valves allows HOT filling, COUNTER PRESSURE filling and GRAVITY filling. The UNICA SA filler is designed to change formats easily. Several capping and rinsing solutions are available for the safety of the package.

| Packaging technology | Products/ Containers/ Closures | |

|---|---|---|

| UNICA SA Attention to details and modular design are the characteristics of this machine series. The UNICA SA valve and its advanced and simple LIFTER are at top level between annular tank fillers. UNICA SA series is the machine for clients who need flexibiltiy in term of containers and product. Main Features:

UNICA SA filler versions

|   | Designed for neck handling, Flexible to any application Products:

|

- Container type changeover from GLASS to PET for clients business flexibility

- Height carousel adjustment and easy change part tools for changing formats

- Accurate finishing of the parts give the valve high hygienic properties

- Easy maintenance and wear and tear parts replacement

- Seals and seal sites designed and manufactured with high duration materials and hygienic properties

go back to filling machine series list

UNICA TRONIC rotating filler

The UNICA TRONIC machines is designed to fill any kind of bottles with the maximum hygiene performances. The filling machine can be sized from 20 to 120 UNICA TRONIC SA filling valves. UNICA TRONIC valves are advanced devices using FLOW METERING technology. The inner parts of the valve are clean and without acute angles and grooves. The machine is designed for gravity filling WITHOUT CONTACT BETWEEN VALVE AND CONTAINER. Any kind of rinsing and cleaning treatment can be integrated in the machine. A wide series of capping possibilities and cap treatment complete the machine for the best hygiene and shelf life.

| Packaging technology | Products/ Containers/ Closures | |

|---|---|---|

| UNICA TRONIC The machine works on the principle of flow meters. The quantity of product passing trough special connections in measured by the flow meters. The valve opens and closes gradually to control foaming. The clean design of the valve elements allows filling of sensible products. Different metering technologies are available. Frame and surfaces, the whole design of the machine, is thought to control contamination, inner environment and facilitate sanitation Main Features:

UNICA TRONIC filler versions

|  | Designed SENSIBLE products Products:

|

- NO CONTACT BETWEEN CONTAINER AND FILLING VALVE

- Clean design suitable for filling SENSITIVE PRODUCTS

- Easy maintenance design

- Different options to improve shelf life of the packaging, control inner environment, sanitize caps or containers

- Seals and seal sites designed and manufactured with high duration materials and hygienic properties